HekimPor

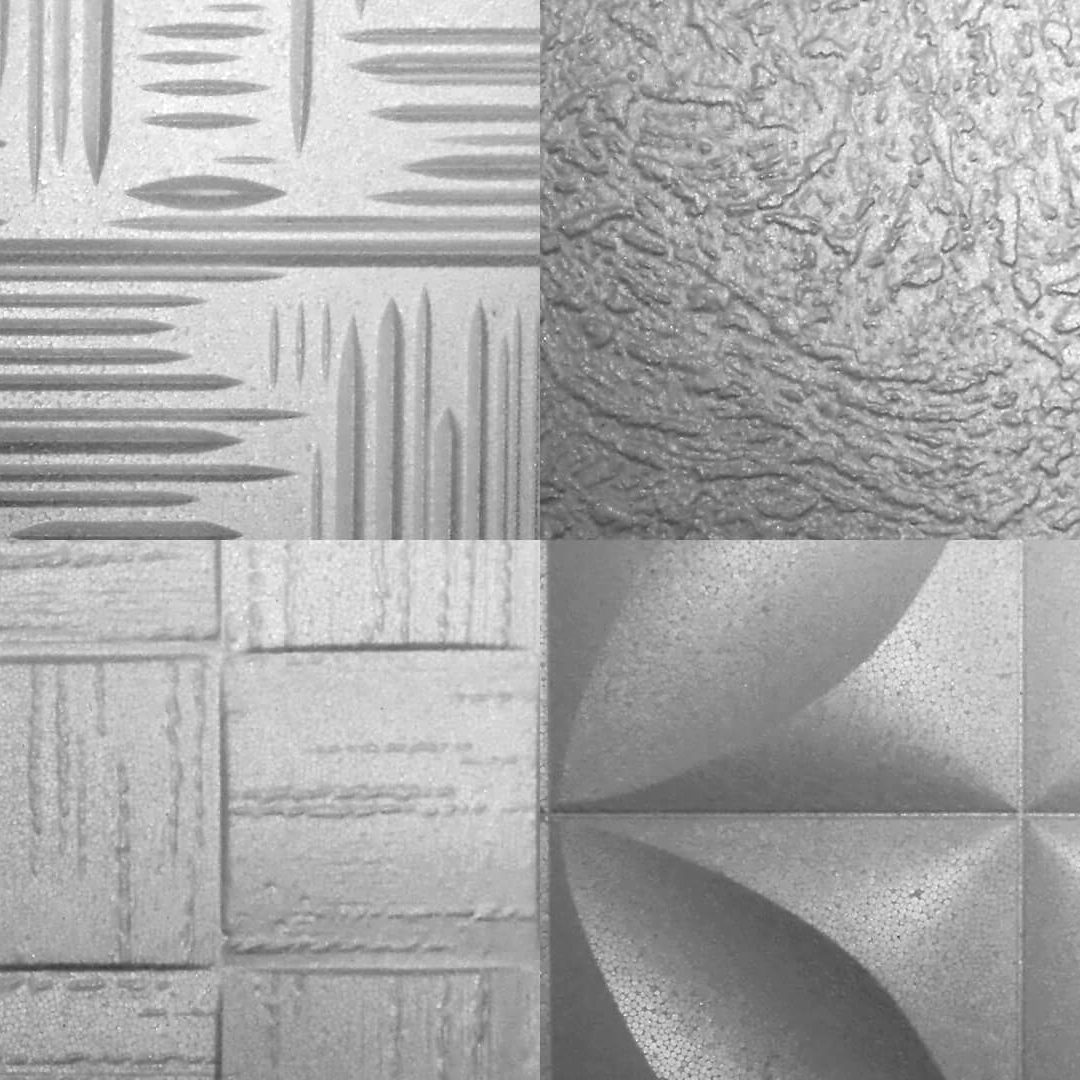

Combination of Insulation and Aesethetics

Product Groups

HekimPor Product Groups

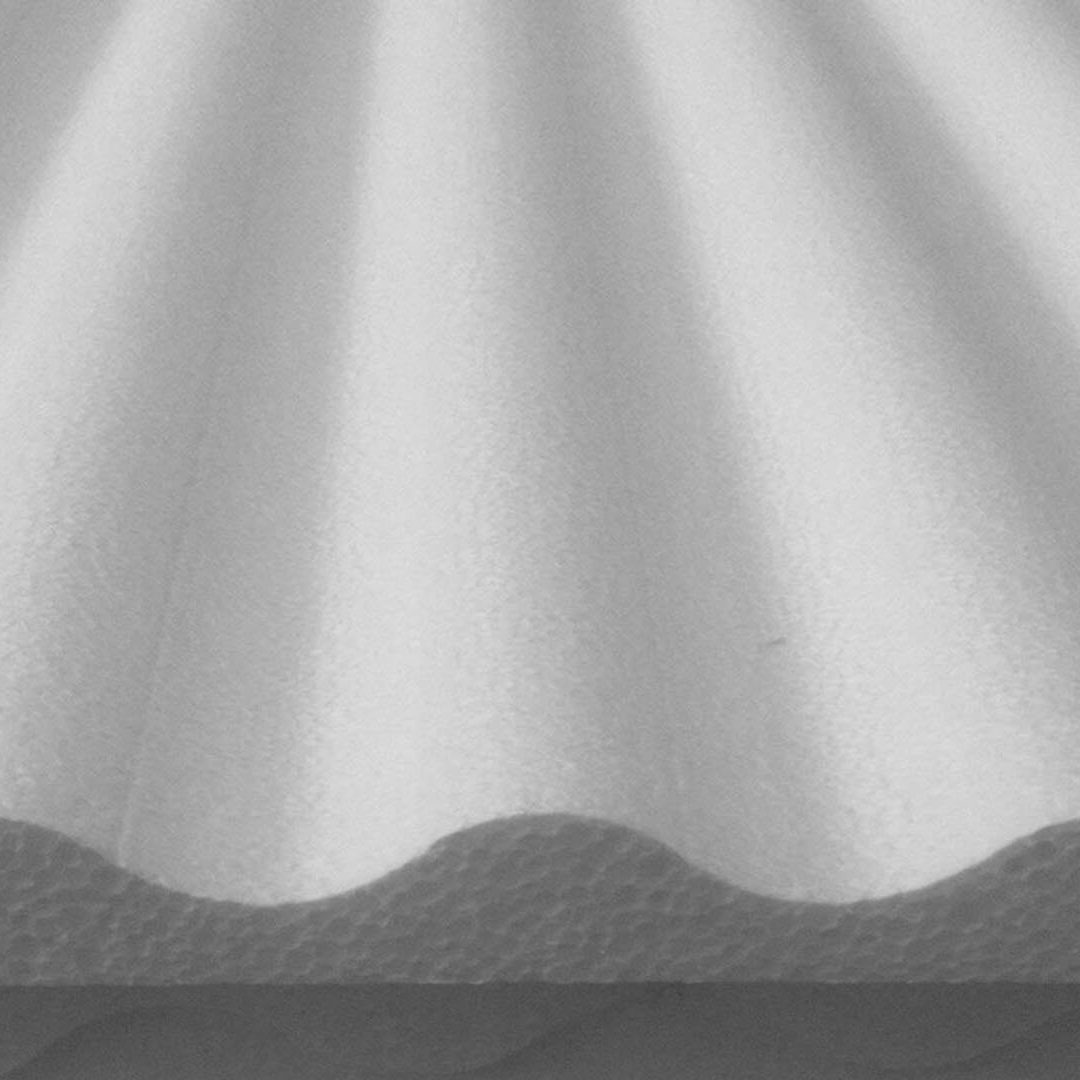

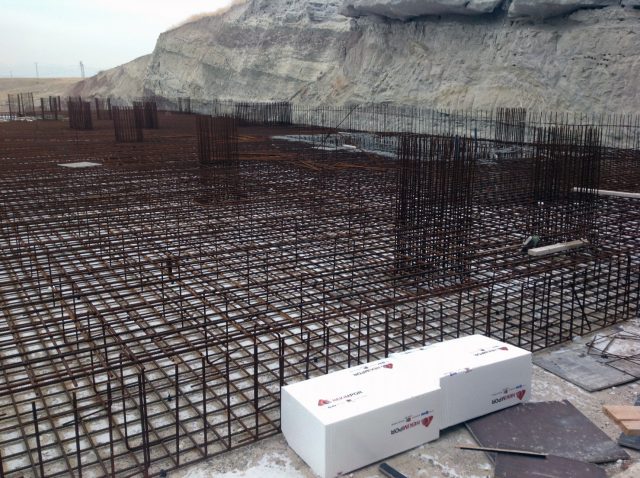

Heat insulation is necessary for the purpose of heating and cooling buildings, saving from energy and fuel expenses. Although investment cost of heat insulation applied on the buildings may seem steep, it will amortize investment cost within 2-3 years and will ensure heat insulation as long as the life of the building. In short, the aim of the heat insulation is to prevent hot air from entering inside in the summers and cold air in the winters. Mould growth and black stains do not form and plaster or paint blistering does not occur as a result of perspiration (moisture) on the surfaces where heat insulation is applied.

HEKIM YAPI, believing that we should be extremely aware about energy saving and environmental pollution, has introduced HERKIMPOR – HEKIMEPS brands to the heat insulation sector. HEKIM YAPI produces EPS (expandable Polystyrene) heat insulation plates in its new 20.000 m2 factory in Hendek 2nd Organized Industrial Zone.

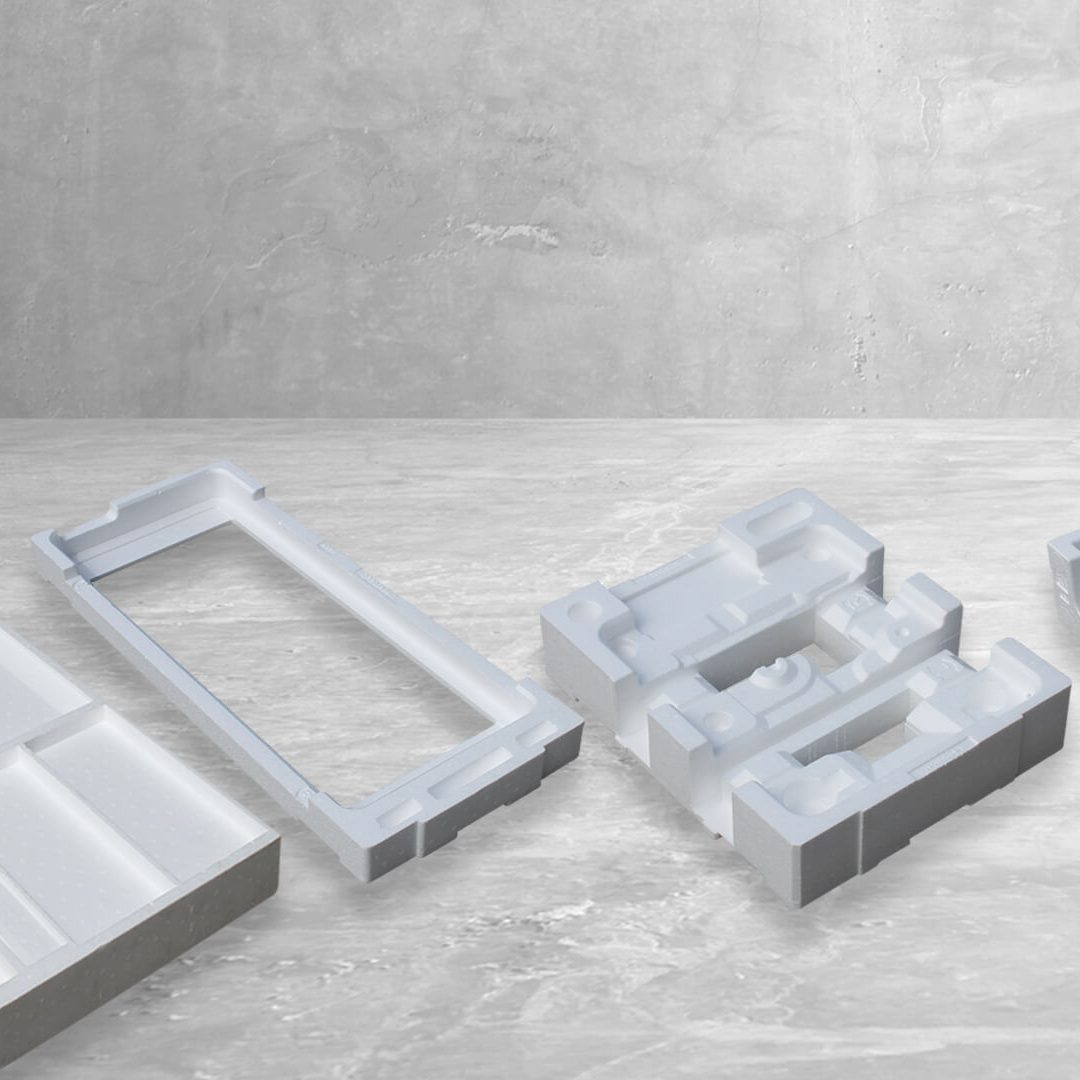

Hekim YAPI offers its products through HEKIMPOR and HEKIMEPS brands. Hekimpor can be produced in the densities of 10-40 kg / m3 and in the thickness of 1-2-3-4-5-6-7-8-9-10 cm. with the method of swelling of polystyrene granules and cohesion of these with injection molding system and provides convenience in heat insulation applications.