20 November 2025 | Blog | 9 Imaging

Easy Applications with HekimPanel on Roofs and Facades of Hangars and Industrial Facilities

Industrial structures with large openings, such as hangars, warehouses, factories and logistics centers, require specialized solutions for both construction processes and operational efficiency. Cladding the facades of these massive structures can be both time-consuming and costly with conventional methods. Critical requirements such as adherence to project schedules, uninterrupted insulation performance and long-term durability necessitate the use of modern and rational building materials. Hekim Yapı, under its HekimPanel brand, developed to address this need, offers innovative sandvich panel solutions that simplify installation and maximize speed and efficiency on hangar roofs and facades.

What is HekimPanel? All-in-One Solution

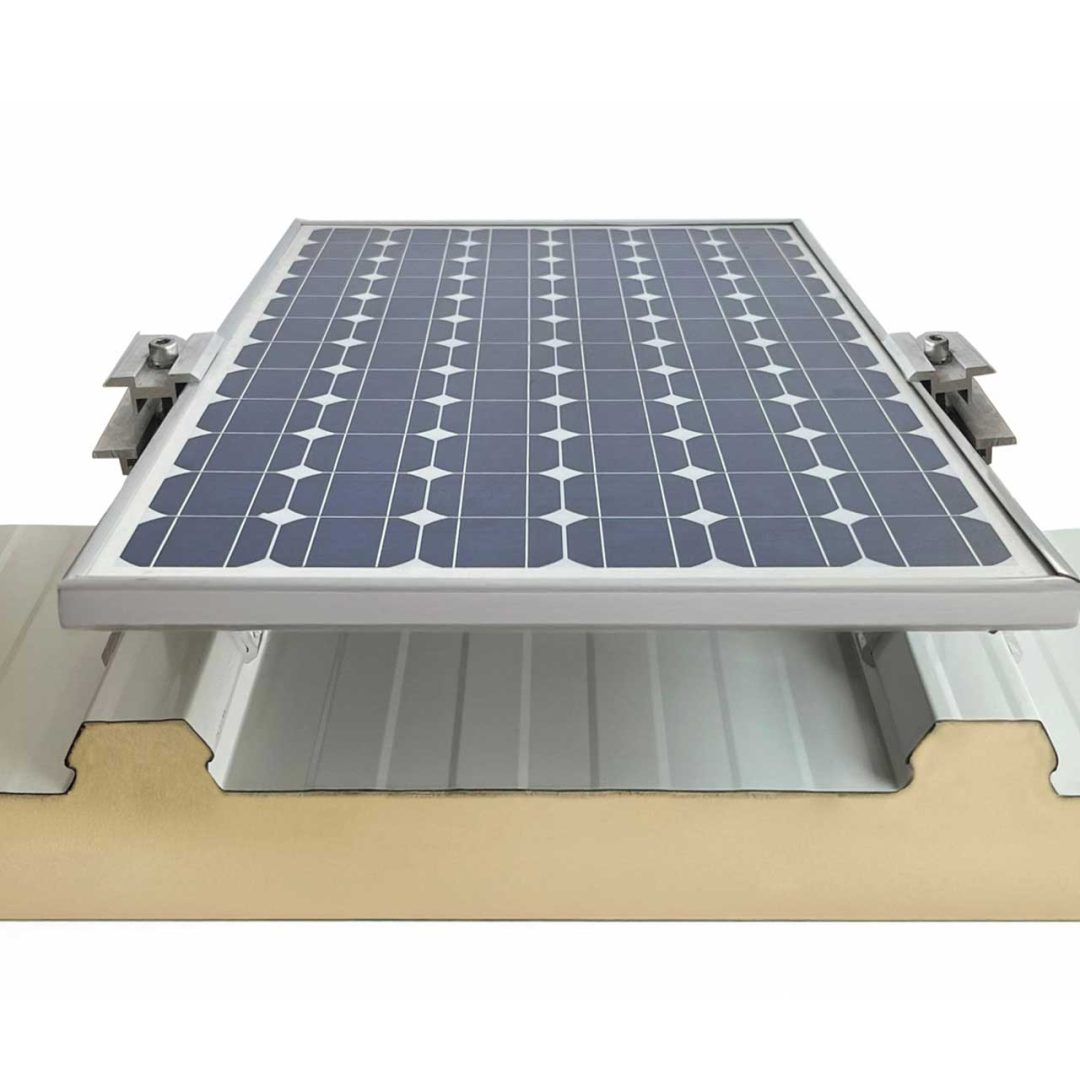

HekimPanel, in its simplest definition, is a composite material created by applying a high-density, superior-insulating core material (PIR, PUR, Stone Wool and EPS) between two metal surfaces. This all-in-one structure distinguishes HekimPanel from conventional exterior cladding methods. A single wall panel serves as an outer shell mounted to the structure’s structural system, a high-performance thermal and acoustic insulation layer, and an aesthetically pleasing interior/exterior finish. This integrated structure eliminates numerous different fabrication elements and labor requirements, such as brickwork, plaster, insulation sheathing and painting. HekimPanel radically simplifies construction processes by offering all facade components required for a hangar project in a single product.

Installation Speed and Its Effect on Project Durations

In projects with large facade areas, such as hangars, time directly means cost. HekimPanel roof and wall panels, manufactured in large sizes yet lightweight, offer a significant speed advantage in installation processes. The panels that are easily lifted onto the structural framework by crane are assembled in a way that ensures quick and complete sealing, thanks to their special connection details. A specialized installation team of several people can cover hundreds of square meters of façade in a single day. This is an incredible speed compared to conventional walling and cladding methods. Completing the project much earlier allows the hangar to become operational on schedule, significantly shortening the return on investment. Hekim Yapı offers a variety of roof and facade panels to meet the needs of every project.

Superior Insulation Performance and Energy Efficiency

Hangars are among the most difficult and costly building types to heat and cool. Even the smallest thermal bridge on the facade or roof leads to significant energy losses and high operating costs. HekimPanel roof and wall cladding panels completely prevent the formation of thermal bridges by means of their seamless insulation core. Insulating fillers such as PIR and PUR offer excellent thermal performance with low thermal conductivity coefficients, while stone wool-filled panels stand out with their high fire resistance and sound insulation properties. This superior insulation performance ensures the hangar maintains its interior temperature with less energy consumption. This brings along significant savings in long-term operating costs and contributes to the sustainability of the building.

Durability, Ease of Maintenance and Aesthetic Diversity

Industrial facilities are structures subject to harsh environmental conditions and mechanical stresses. The high-quality painted sheet metal used on the exterior of HekimPanel provides long-term resistance to corrosion, UV rays and weather conditions. Its smooth surface is easy to clean and does not require additional costs such as periodic paint maintenance. In addition to its functionality, HekimPanel also meets the aesthetic expectations of modern industrial architecture. With diverse color options and surface forms such as micro-ribbed finishes, hangars can be given a dynamic and modern look. Thus, it is not only functional but also serves as an aesthetic decorative roof and wall panel. You can review Hekim Yapı’s experience and aesthetic approach in this field in our reference projects.

A Rational and Efficient Solution for Your Hangar Projects: Hekim Yapı

In conclusion, HekimPanel is the most effective solution for fasades in hangars and similar industrial buildings, offering speed, efficiency, insulation performance and aesthetics all in one. For information on panel types, insulation thicknesses and technical details specific to your project, please contact our expert team through our contact page.