HekimPanel

Hekim Sandwich Panel

Product Groups

HekimPanel Product Groups

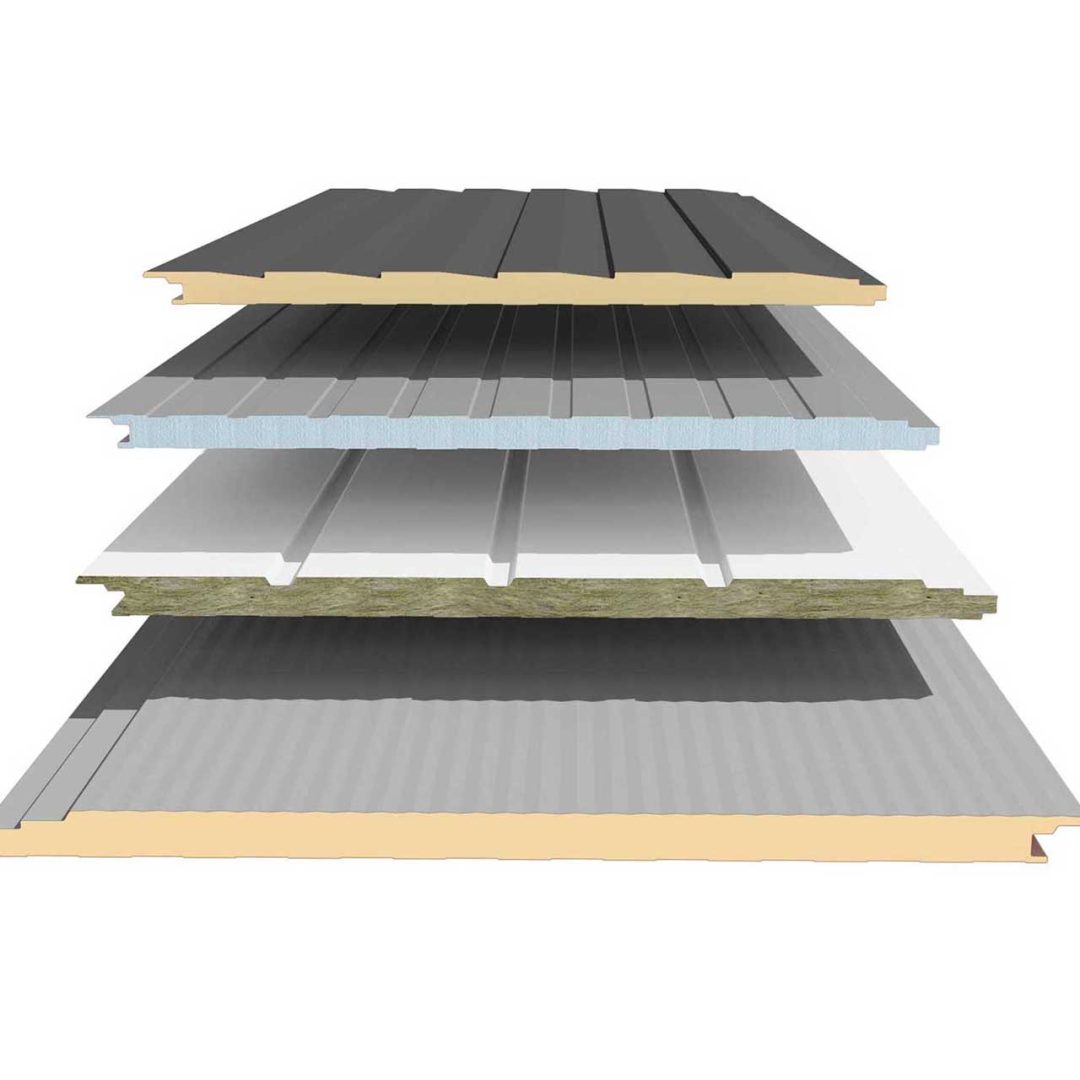

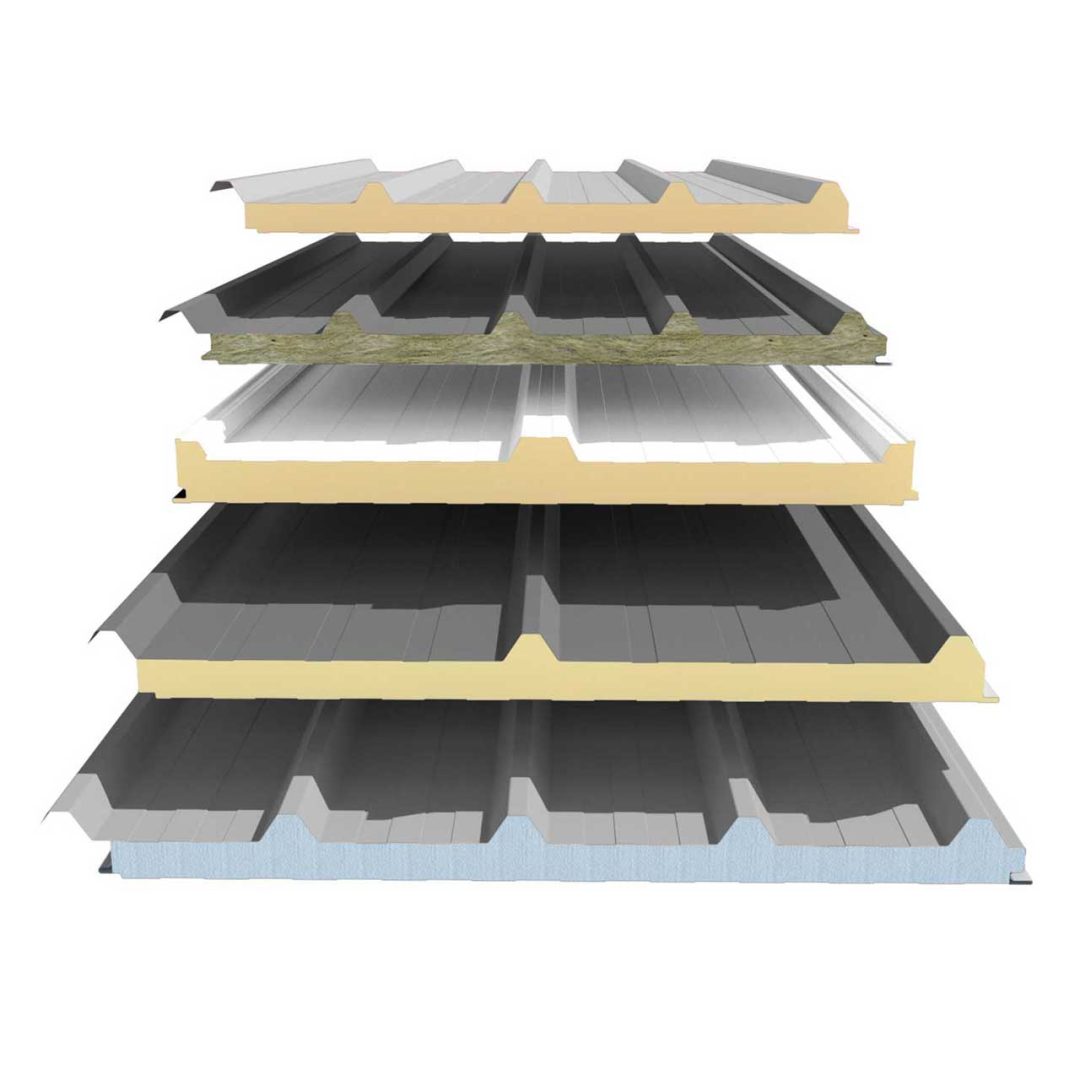

These are sandwich panels which are used on all kinds of interior and exterior façade cladding. They are produced by a continuous production line. The surface materials can be steel, fibercement, PVC or PET.

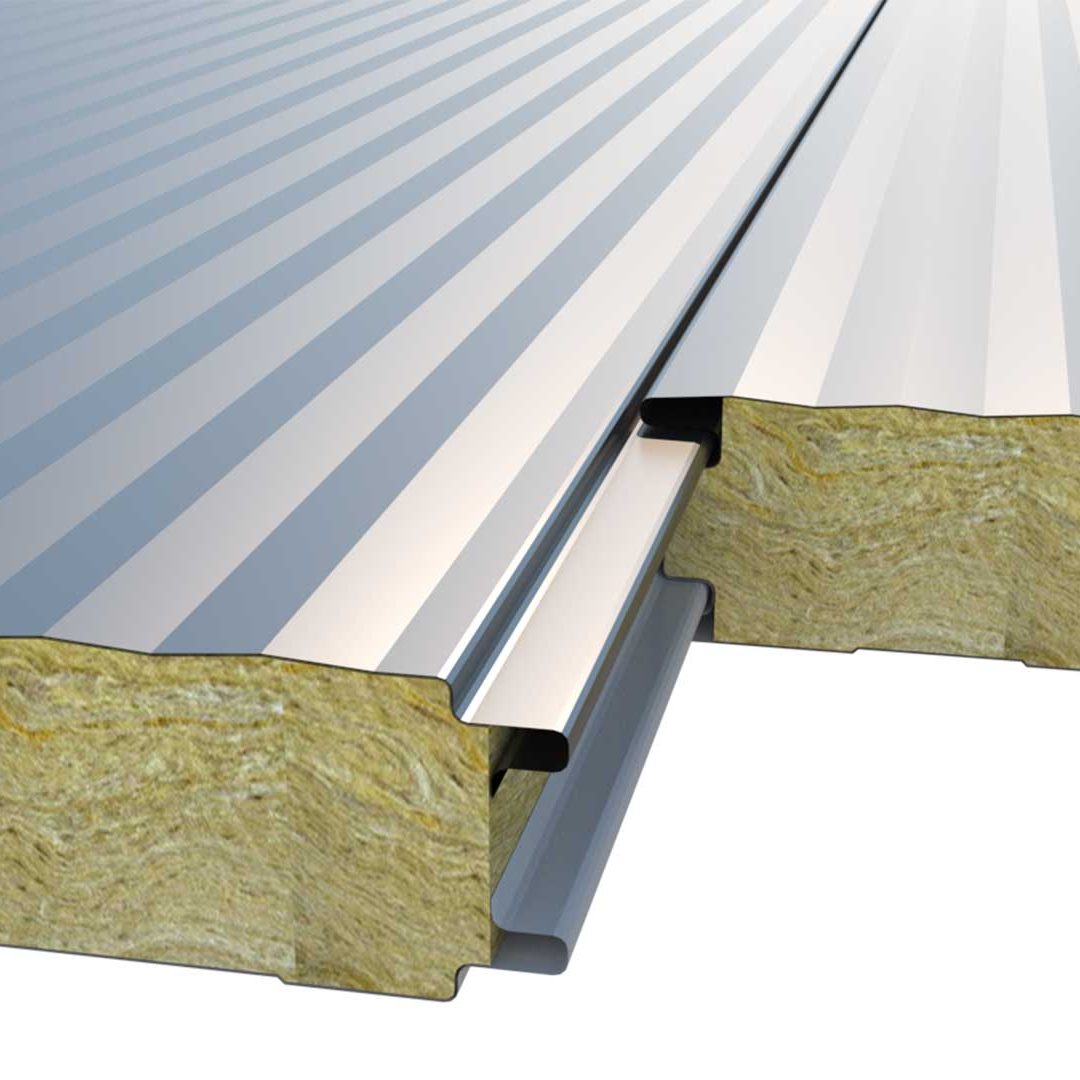

Annual capacity of sandwich panel production plant is 4.000.000 m2. The dimensional capacity of the production line 600-1250 mm in width and 16.000 mm in length. 3 or 5 ribbed roof panels and three different types of wall (façade) panels (“H” type, hidden screw and self-locking system) from a thickness of 40 mm to 150 mm can be produced. Our products offered to the market with HEKIMPANEL brand will present the most affordable solutions in the shortest time to the demands of final users, who need various products, by bringing a new dynamic to the market with many various alternating options.

Quality Certificates

HekimPanel Quality Certificates

Laboratory Studies

HekimPanel Laboratory Studies

HEKIMPANEL continuously carry studies aimed at providing customer satisfaction, expectations and quality at the top level. In addition, our first target is to cover all processes starting from design stage to production, marketing and after sales services with our competent dealer network and to satisfy our customers from their first contact with our company until goods are delivered to them.

HEKIMPANEL have ISO9001:2008 Quality Management System certificate and TS EN 14509/AC:2009 Factory Made Product – Self-Supporting Double Sided Metal Coating Insulating Panels– TSE Conformity Certification indicating all quality control stages are maintained in our company from raw materials to processing and consignment of goods. Within this frame we have established our laboratory to carry out the tests related to the certification in our plant. Besides, surface mechanical properties, shear strength and shear module, compression strength and module, tensile strength,creep, capacity of bending moment on a central support, reaction to the fire tests are performed according to TS EN 14509:2009 standards in TSE, İTÜ and TÜBİTAK laboratories.

Related tests are always performed in accordance with TS EN 14509:2009 requirements especially in our laboratories. Continuous quality control and production inspection are carried out in the entire production line from raw materials to final product.

HEATING VALUES AND REQUIRED TIME AND THEN CONTROLLING PROCESS IS APPLIED.

Transportation, Storage and Protection

Transportation, Storage and Protection Instructions

Hekim Panel is produced in accordance with TS EN 14509, TSE–ISO 10002 Customer Satisfaction Management System, and the materials are loaded to vehicles with utmost care. After transportation, products must ve carefully unloaded at work site, and panels must be properly protected against rain, mud, etc., environmental conditions until installation.

Hekim Panel is produced in accordance with TS EN 14509, TSE–ISO 10002 Customer Satisfaction Management System, and the materials are loaded to vehicles with utmost care. After transportation, products must ve carefully unloaded at work site, and panels must be properly protected against rain, mud, etc., environmental conditions until installation.

Important Notice!

Attention must be paid to ensure that all installation surfaces are facing same direction after removing protective film during installation. There might be color shade differences in panels delivered in batches as they belong to different batches. Panels from the same batch should be used or attention should be paid to dates and warning labels.

Important Notice!

Attention must be paid to ensure that all installation surfaces are facing same direction after removing protective film during installation. There might be color shade differences in panels delivered in batches as they belong to different batches. Panels from the same batch should be used or attention should be paid to dates and warning labels.

Protect the material against sling damages, and place the bottom carriers according to dimensions when a crane is employed for lifting.

Cranes should be used to unload the materials delivered in stacks on vehicles to to work site, to place them on rooftop or to unload straight from vehicle to rooftop.

In particular, use of suitable cranes for stacks exceeding 8 meters minimize material damage during transportation.

Forklifts equipped with wide forks (~3.5 m) can be used to unload packages with stacking lengths between 6-8 meters, and forklifts equipped with narrow forks (~1.2 m) can be used to unload packages with stacking lengths under 6 meters. If forklifts are to be used for unloading, ensure that the length of stacks extending beyond fork tips is not more than 2.5 meters.

Points of consideration when using crane;

Protect the material against sling damages, and place the bottom carriers according to dimensions when a crane is employed for lifting.

Cranes should be used to unload the materials delivered in stacks on vehicles to to work site, to place them on rooftop or to unload straight from vehicle to rooftop.

In particular, use of suitable cranes for stacks exceeding 8 meters minimize material damage during transportation.

Forklifts equipped with wide forks (~3.5 m) can be used to unload packages with stacking lengths between 6-8 meters, and forklifts equipped with narrow forks (~1.2 m) can be used to unload packages with stacking lengths under 6 meters. If forklifts are to be used for unloading, ensure that the length of stacks extending beyond fork tips is not more than 2.5 meters.

Points of consideration when using crane;

- Following dimensions and adapter sizes should be observed in order to ensure a balance lifting of the stack using crane. Number of adapter panel connection points should be minimum 3 for panels over 9 m.

- Nylon, fiber or silk ropes, steel or chain ropes should be employed.

- In order to prevent damages on material edges that may be caused by ropes, wooden wedges should be placed at the bottom and top of the stack where the ropes contact panels as indicated in the following drawing, and wedges that extend 3-5 cm beyond the stack ends should be preferred.

- If the materials are to be moved on the roof in stacks, ensure that stack weight is distributed to carrier system equally and stacks are not placed on scissors. It is recommended to adjust inter-stack spaces to ensure minimum horizontal load bearing on the roof in terms of occupational safety and workmanship.

If the pallet is shorter than the material stack, lift from two ends, if the pallet is longer, lift from corners and center, and never drag. Dragging may cause scratches particularly on painted panels.

If the pallet is shorter than the material stack, lift from two ends, if the pallet is longer, lift from corners and center, and never drag. Dragging may cause scratches particularly on painted panels.

Panels longer than 4 meters should be moved and transported for assembly by minimum three people. First, it should be lifted vertically along its width, then moved vertically as illustrated below.

Panels longer than 4 meters should be moved and transported for assembly by minimum three people. First, it should be lifted vertically along its width, then moved vertically as illustrated below.

- Material should not be grabbed and dragged from one side.

- Likewise, materials should not be pulled or dragged over horizontal beams once they are placed on the rooftop.

- Short materials (≤ 4m) should be grabbed from two ends, longer materials should be grabbed from two ends and from center in a balanced manner when lifting them from the stack or transporting them on to rooftop.

- Do not step on or walk over the bottom material when transporting materials.

- If there are flaps provided on panels for lengthwise placement on the roof, panel should be lifted from those flaps.

If the materials will not be installed right away, they should be stacked in a suitable place at work site where they will not required to be moved again. Panel stacking and installation should be carried out using equipment that will prevent damages on the connection edges. Panels that are damaged on connection ends during stacking or installation should not be installed. Otherwise, visual flaws may occur on panel surfaces.

The first choice should be an indoor storage for long term storages. Additionally, materials and storage area should be prevented against air flows. (Temperature difference in stock area should not be more than Δ 10 °C, and relative humidity should not be more than 70%.) The reason for indoor stocking and prevention of air flows is to prevent water introduction and accumulation between two materials. Water or humidity between two panels may lead to paint blisters at material contact points. Such blisters can damage material structure and visual flaws.

If the panels are to be stored outdoors for more than few days, they should be covered under nylon covers in a way to prevent contact with other materials or blocking of air flow.

In particular, painted sheet panels with protective film should be protected against sun light. Thin polyethylene protective film on painted sheets will adhere on panels more strongly if exposed to sun light for extended periods, making them difficult to remove.

If the materials will not be installed right away, they should be stacked in a suitable place at work site where they will not required to be moved again. Panel stacking and installation should be carried out using equipment that will prevent damages on the connection edges. Panels that are damaged on connection ends during stacking or installation should not be installed. Otherwise, visual flaws may occur on panel surfaces.

The first choice should be an indoor storage for long term storages. Additionally, materials and storage area should be prevented against air flows. (Temperature difference in stock area should not be more than Δ 10 °C, and relative humidity should not be more than 70%.) The reason for indoor stocking and prevention of air flows is to prevent water introduction and accumulation between two materials. Water or humidity between two panels may lead to paint blisters at material contact points. Such blisters can damage material structure and visual flaws.

If the panels are to be stored outdoors for more than few days, they should be covered under nylon covers in a way to prevent contact with other materials or blocking of air flow.

In particular, painted sheet panels with protective film should be protected against sun light. Thin polyethylene protective film on painted sheets will adhere on panels more strongly if exposed to sun light for extended periods, making them difficult to remove.

- Do not place more than 3 stacks over each other. Total height should be max. 2.7 cm.

- Wedges should be placed to give an inclination to the stacks. (~%2-3)

- Wedge height should be 6-10 cm, and wedge spacing should be maximum 1.5 cm.

- If there is a wooden pallet underneath the stack, wedges in equal height to the pallet should be placed under stack corners extending beyond the pallet.

- Wedges between the stacks should be placed in vertical alignment.

- Styrofoam wedges should be used.

- Do not step on or walk over the panels.

- Panels must be placed on level surfaces.

Protect panels against external impacts even during short periods of storage, preferably place on a slightly inclined surfaces.

The panels longer than 4 meters should be replaced or carried for assesmbly by at least 3 people. First, they should be lifted upright and transversely and carried vertically as follows.

The panels should be checked whether the product type, quantity, color and thickness corresponds to the dispatch note and order before unloading and assemblying them and if there are differences, should be informed. Hekim Yapı may not held responsible from nonconforming product notice made after unloading or assemblying.

The assembly of the wall panels should be made by fixing panels to horizontal and vertical lifting apparatuses depending on the assembly direction or by lifting the panel with vacuum lifting system and lifting ropes. Before starting to assembly, should be paid attention the length and smoothness of the purlines, elevation difference between purline and the purlin and the eaves channel are in the same plane, the structure is in the rope and miter horizontally and plumb line and vertically on the facade. The panels should not be assembled to the inappropriate buildings, if possible, they should be determined and corrected priorly.

If possible, the panels should be cut on the construction site. If cutting will be made, HekimPanel is not responsible from scratches, fractures and deformations caused by cutting.

The panels longer than 4 meters should be replaced or carried for assesmbly by at least 3 people. First, they should be lifted upright and transversely and carried vertically as follows.

The panels should be checked whether the product type, quantity, color and thickness corresponds to the dispatch note and order before unloading and assemblying them and if there are differences, should be informed. Hekim Yapı may not held responsible from nonconforming product notice made after unloading or assemblying.

The assembly of the wall panels should be made by fixing panels to horizontal and vertical lifting apparatuses depending on the assembly direction or by lifting the panel with vacuum lifting system and lifting ropes. Before starting to assembly, should be paid attention the length and smoothness of the purlines, elevation difference between purline and the purlin and the eaves channel are in the same plane, the structure is in the rope and miter horizontally and plumb line and vertically on the facade. The panels should not be assembled to the inappropriate buildings, if possible, they should be determined and corrected priorly.

If possible, the panels should be cut on the construction site. If cutting will be made, HekimPanel is not responsible from scratches, fractures and deformations caused by cutting.

- Please pay attention that the assembly surfaces are on the same facade after removing the protective films on the panels during the assembly. Due to the panels coming on party basis are separate panels, there may be shade differences on the paint. The panels from the same party always should be used or should be paid attention to the dates and warning labels.

- The material should not be pulled by holding one end.

- While placing the material on the roof, they should not be slipped or pull on the purlines.

- While lifting the material from the stack or carrying to its place on the roof, the short materials ( ≤ 4 m) should be held from two edges, the long materials (> 4 m) should be held from two edges and middle balancedly.

- While carrying the material, it should not be stepped or walked on the material under it.

- If the brackets were left on the panels in order to overlap them, the panel should not be held from this bracket.

- During the assembly, any cutting should not be made with lathe grinder or similar sparking machine on the panels. If it is made accidentally, cutting burrs should be removed and repainted. Otherwise, the burrs formed after cutting adhere to the surface, damages the paint and rusts over time.

Warning and Information For Dark-Colored Panels

The panel surface colors are basically separated as very light colored, light colored and dark colored panels.

Warning and Information For Dark-Colored Panels

The panel surface colors are basically separated as very light colored, light colored and dark colored panels.

| Very Light Color Group Ral Codes: | 1013-1015-1016-6019-7035-7047-9001-9002-9003-9010 |

| Light Color Group Ral Codes: | 1002-1003-1004-1014-1017-1021-1023-2003-2004-2008-2009-5012-5018-5024-6018-6021-7000-7040 |

| Dark Color Group Ral Kodları: | 3000-3002-3004-3009-3005-3011-5002-5003-5010-5017-6000-6002-6005-6029-7012-7015-7016- |

| 7021-7022-7026-7043-8001-8003-8011-8012-8015-9004-9005-9006-9007-9017 |

| In winter | T1= 0°C , -10°C, -20°C ve -30°C’dir. |

| Very Light Colors | T1 = +55°C |

| Light Colors | T1 = +65°C |

| Dark Colors | T1 = +80°C |

| For each color group | temperature difference between inner surface and outer surface (Δt) . |

| Very Light Colors | Δt = 35°C (55-20 ) |

| Light Colors | Δt = 45°C (65-20) |

| Dark Colors | Δt = 60°C (80-20) |

- The panel thickness and metal thickness should be selected in accordance with the static tables in the project. Especially, the outer sheet should be 0,60 and above at rockwool panels and 0,50 at in polyurethane panels accordint to the color and project status. It is recommended to be 0,60 and above at dark colored panels.

- In order to minimise the thermal load, should be assembled in hot weathers. It should be minimum +10 °C and above. If possible, it should be made in clear and sunny weather.

- The panel lengths should not exceed 6 meters on the facade. If it will exceed, the metal thickness should be increased and also if it is polyurethane, the strong forms should be preferred (Such as micro-printed 5 fluted facade form). Or, the length should be determined by considering the thermal load. Especially, the number of the purline should be kept at minimum for dark colored facade panels (6 screw points and above including top and bottom peak points are accepted as long panel and bear high risk) other loads should be solved by increasing the panel thickness and panel metal thickness. Thermal load is minimal at one gap. There is no height limitation in full sinus form facade panels.

- The construction where the panel will be made should be faultness and in vertical and horizantal direction.

- While unloading panels and storing at site, it should be paid utmost attention to the rules.

- Even if all these conditions are met, HekimPanel does not guaranty homogene smoothness for dark colored panels and does not accept any responsibility.

Technical Details

HekimPanel Technical Details

| Metal type: | Painted Galvanized Sheet 0,40-0,50-0,60-0,70-0,80-0,90-1,00 mm thickness |

| Paint type: | Polyester ( 7 micron primer + 10 micron topcoat ), PVDF or Plastisol |

| Color: | RAL Catalogue colors |

| Protection: | Protective polyethylene foil can be applied on one or two surfaces, if possible, to protect from possible damages during transportation and assembly. |

| Insulation Type: | Rock Wool or EPS |

| Density: | Rock Wool 110 kg / m3 – EPS 16 kg / m3 |

| Incombustibility Class: | Rock Wool A2S1d0 class – EPS E class |

| Thickness: | 40 – 50 – 60 – 70 – 80 – 100 – 120 mm |