HekimBoard

Fibercement Board

Product Groups

HekimBoard Product Groups

Fibercement is a global term which describes the fiber reinforced cement products and commonly used in all the countries around the world. Common feature of these plates is having organic or inorganic (or both) fibers in their structures as reinforcement elements and Portland cement as a bonding member.

Fibercement is a global term which describes the fiber reinforced cement products and commonly used in all the countries around the world. Common feature of these plates is having organic or inorganic (or both) fibers in their structures as reinforcement elements and Portland cement as a bonding member.

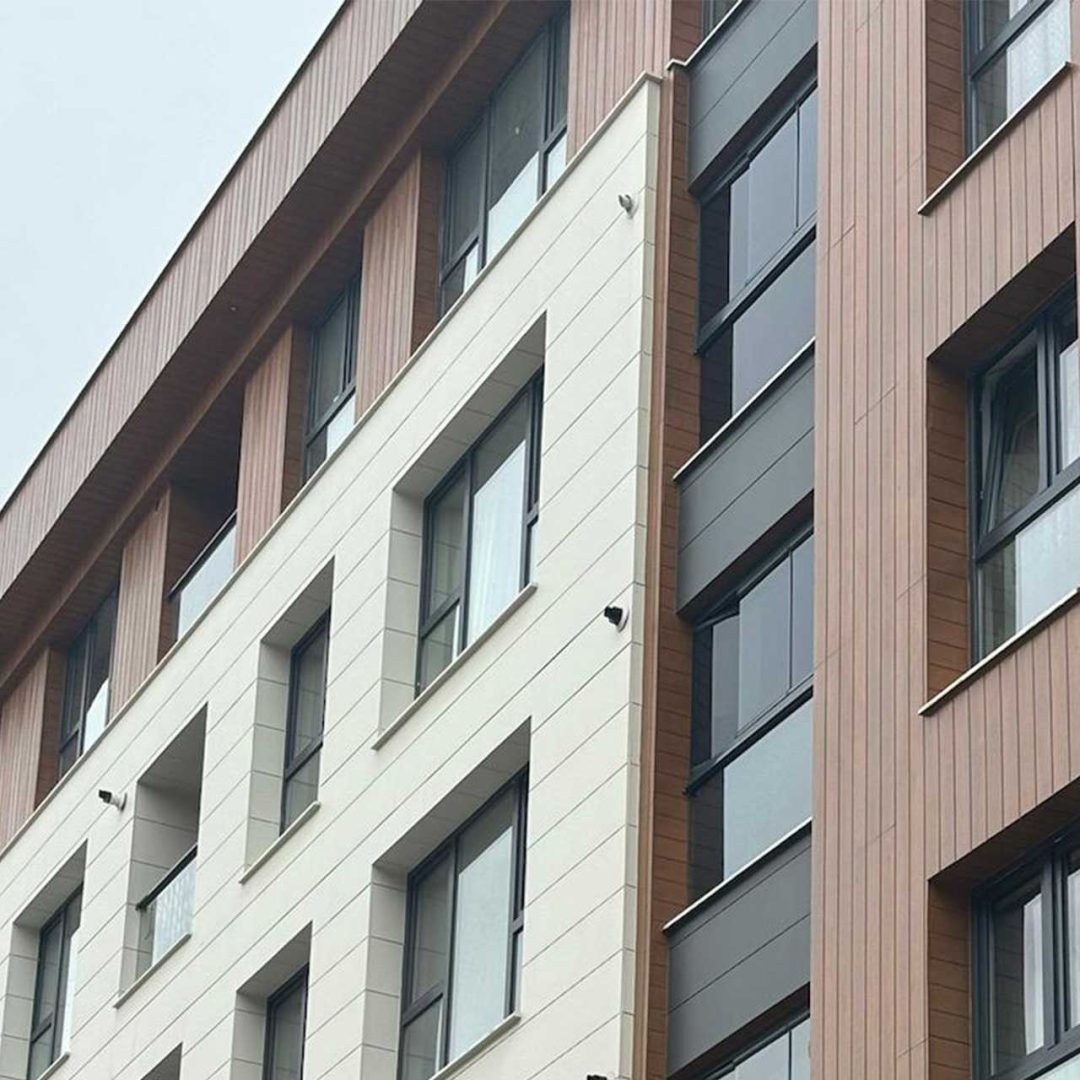

Large sized plates that can be used on the interior and exterior facade cladding applications of all kinds of buildings are produced under HEKIMBOARD brand. Plates with 1250 mm standard width are produced in two different lengths of 2500 mm and 3000 mm. Production of non-standard dimensions out of these figures may also be possible. Plates have various kinds in terms of their place of use (interior or exterior applications) and surface appearance.

Plates separated into two categories as interior and exterior according to their place of use are also produced in various surface appearances. Exterior plates specify plates which will be exposed to atmosphere conditions directly. Although their general formulations are largely identical, some chemicals are added to keep thermal expansion values at the minimum level. The plates produced in this category are referred as A-category plates in TS EN 12467 standard. Interior plates are described as plates not expected to be exposed directly to atmosphere conditions. These products described as C category plates in the related standard can be used on the interior facade cladding, as supporting material under roofing material and as backer boards under the tiles in wet areas or as ceiling covering plates.

Superior Features

HekimBoard Superior Features

Technical Characteristics

HekimBoard Technical Characteristics

| Title | Value |

|---|---|

| Standard Dimensions: | Plain and Patterned: 1250 x 2500 mm, 1250 x 3000 mm |

| Thickness : | Plain: 6 ~ 20 mm – Patterned: 8 ~ 12 mm |

| Length / Width Tolerance: | ± 5 mm / ± 3,75 mm |

| Thickness Tolerance (e: board thickness): | Plain: ± %10 e, Patterned: – %10e / +%15e |

| Right Angle Deviation: | ± 2 mm/m |

| Straighness of the Sides: | ± % 0,1 a ( a : side length ) |

| Surface Appearance: | Plain or patterned |

| Density: | ~ 1350±50 kg/m3 |

| Vapor Diffusion Resistance Factor: | μ ≤ 30 |

| Porosity: | ~ % 30 |

| Bending Resistance ( Minimum ): | ~ 14,0 N/mm2 ( boyuna ); ~ 9,0 N/mm2 ( enine ) |

| Free-Resistance: | Freeze Resistant in accordance with TS EN 12467 |

| Water Impermeability: | Impermeable to water in accordance with TS EN 12467 |

| Flame Resistance: | Incombustible, A1 class building material according to EN 13501-1 |

| Asbestos Content: | Does not contain asbestos ( NT type plate ) |

| Emission of Other Hazardous Substances: | No emission of hazardous substances or gases |

| Coefficient of Thermal Expansion: | αt = 0,005 mm/mK |

| Coefficient of Heat Transmission: | λ = 0,20 W/mK |

| Modulus of Elasticity: | 8000 N/mm2 ( longitudinal ), 6000 N/mm2 ( horizontal ) |

| Water Absorption Rate: | < % 30 |

| Humidity Rate of Boards in Stock: | < %10 ( subject to atmospheric humidity ) |

| Water Effect: | 0,5 mm/m ( in full saturation ) |

| Bending Radius (According to Thickness): | 8 mm.. 8 m; 10 mm..12 m; 12 mm..24; 16 mm..50 m |